From laboratory waste to recyclable material: Research allowance from the Federal Republic of Germany for Starlab.

Author:

Klaus Ambos

President & CEO Starlab

Key topics: Sustainability, Laboratory recycling, Polypropylene, TipOne® pipette tips

Category: Sustainability

Date: 23/01/2025

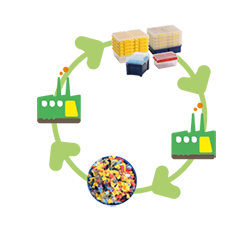

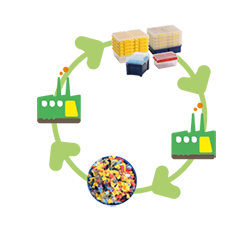

After more than 1,670 laboratories collecting over 100 tonnes of plastic, Starlab has now succeeded for the first time in producing a high-quality laboratory product from the collected recycled material.

For the first time, the laboratory product manufacturer can thus close the recycling loop for its TipOne® pipette tip racks. Starlab's recycling service for the collection of TipOne® system polypropylene components is not only popular with researchers – but also well received by the German government. The company has received a significant research allowance from the Federal Republic of Germany.

Industry’s first research allowance for sustainable recycling

With its funding, the Research Allowance Certification Office (Bescheinigungsstelle Forschungszulage (BSFZ)) honors Starlab's many years of development work in the field of sustainable laboratory waste management. As part of the Research Allowance Act (Forschungszulagengesetzes (FzulG)), Starlab is the first company in the industry to receive this recognition – a confirmation of the path it has taken towards closed loop cycles for laboratory material.

The recognition shows that in times of climate crisis, plastics are not always part of the problem, they can also be part of the solution. "For a long time, it was said that plastic products could not be sustainable. We have proven that it depends on the right concept and new ways of thinking. Above all, we invested in the future at an early stage, because sustainability means the future," explains Klaus Ambos, Managing Director of Starlab International GmbH. Starlab, known for its TipOne® pipette tips, which made a significant contribution to maintaining PCR test capacities during the Corona pandemic, redesigned the tip system in 2015 with long-term sustainable goals, and has gradually implemented steps towards the closed loop over the years. The special challenge here is that laboratory plastics must meet the highest quality and purity standards. The company has managed to combine these requirements with the principles of the circular economy.

10 years of work: from creation to use

With the introduction of the sterile refill system in 2015, Starlab added another important building block to its sustainability strategy. A special design ensures that the high sterility requirements in the laboratory are met at all times although very little plastic is used to protect the tips. "From the very beginning, acceptance among our customers was higher than their skepticism. In science and research, there is courage and the will to become more sustainable," explains Ambos. "Laboratories are quite willing to break new ground – if the quality is right and if the research work does not suffer as a result."

From waste to collection: Number of laboratories increases significantly

Launched in 2020, the Starlab Recycling Service is the link in the material cycle. As part of the service, which Starlab has currently established in Germany, Austria, France and the UK, laboratories systematically collect their TipOne® plastic waste. "The number of participating laboratory facilities increased to over 1,670 in 2024 – a threefold increase compared to 2022," reports Dr. Lennart Walter, Project Manager for TipOne® Recycling at Starlab.

From ‘waste’ to resource

The collected TipOne® polypropylene (PP) material is processed into high-quality recyclate. "The consistent use of high-quality PP in our TipOne® system enables direct and efficient processing into high-quality PP material that is as good as new. This year alone, we have exceeded the mark of 100 tonnes of recycled regrind," says Walter. Since the beginning of the year, the regrind has been used for the first time in the production of TipOne® racks. This closes the loop, and recycled material from the laboratories returns, goes back to them in the form of new racks.

National strategies to reduce primary raw material consumption

The timing for this milestone could not be better: It was only on 4 December 2024 that the German government adopted the National Circular Economy Strategy (Nationale Kreislaufwirtschaftsstrategie (KWS)), which aims to reduce the consumption of primary raw materials and close material cycles.

Also, in November 2024, the UK government announced the formation of the Circular Economy Taskforce to support the government in creating a circular economy strategy for the UK. "Our customers want to know what happens to the plastic they collect," explains Ambos. "Our system enables a completely transparent cycle – from raw material to use to recycling and reuse. This is our contribution to a more sustainable and crisis-proof economy."

Tips and more.

More on sustainability.

Discover's Starlab's green mission, products and services and get to know our Green Team. We look forward to a joint #EcolutionMovement.

Podcast: Sustainability in laboratories.

A deep dive with Klaus Ambos, CEO Starlab Group, with biochemist Nikoline Borgermann aka Avasustain.