-

59

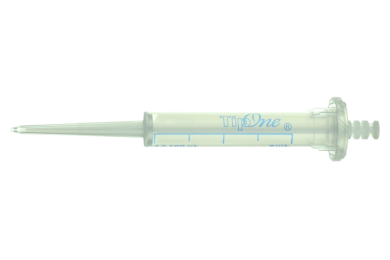

5.0 ml TipOne® Repeat Dispenser Tips (non-sterile)Art. No.: S4751-0500 Volume: 5.0 ml Sterile: No Pack Type: Bag£33.95 instead of £82.76 Promotional price shown. [*plus VAT and shipping]

5.0 ml TipOne® Repeat Dispenser Tips (non-sterile)Art. No.: S4751-0500 Volume: 5.0 ml Sterile: No Pack Type: Bag£33.95 instead of £82.76 Promotional price shown. [*plus VAT and shipping] -

59

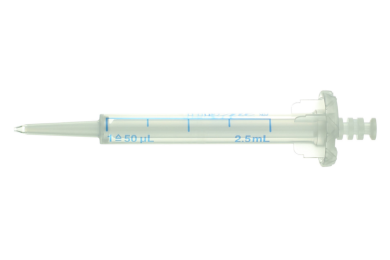

2.5 ml TipOne® Repeat Dispenser Tips (non-sterile)Art. No.: S4751-0250 Volume: 2.5 ml Sterile: No Pack Type: Bag£33.95 instead of £82.76 Promotional price shown. [*plus VAT and shipping]

2.5 ml TipOne® Repeat Dispenser Tips (non-sterile)Art. No.: S4751-0250 Volume: 2.5 ml Sterile: No Pack Type: Bag£33.95 instead of £82.76 Promotional price shown. [*plus VAT and shipping] -

59

1.0 ml TipOne® Repeat Dispenser Tips (non-sterile)Art. No.: S4751-0100 Volume: 1.0 ml Sterile: No Pack Type: Bag£33.95 instead of £82.76 Promotional price shown. [*plus VAT and shipping]

1.0 ml TipOne® Repeat Dispenser Tips (non-sterile)Art. No.: S4751-0100 Volume: 1.0 ml Sterile: No Pack Type: Bag£33.95 instead of £82.76 Promotional price shown. [*plus VAT and shipping] -

59

0.5 ml TipOne® Repeat Dispenser Tips (non-sterile)Art. No.: S4751-0050 Volume: 0.5 ml Sterile: No Pack Type: Bag£33.95 instead of £82.76 Promotional price shown. [*plus VAT and shipping]

0.5 ml TipOne® Repeat Dispenser Tips (non-sterile)Art. No.: S4751-0050 Volume: 0.5 ml Sterile: No Pack Type: Bag£33.95 instead of £82.76 Promotional price shown. [*plus VAT and shipping] -

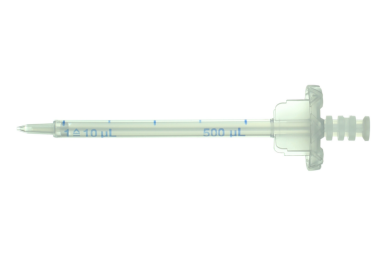

0.1 ml TipOne® Repeat Dispenser Tips (non-sterile)Art. No.: S4751-0010 Volume: 0.1 ml Sterile: No Pack Type: Bag

0.1 ml TipOne® Repeat Dispenser Tips (non-sterile)Art. No.: S4751-0010 Volume: 0.1 ml Sterile: No Pack Type: BagOn request

We are closing the loop!

We are thrilled that we have closed the material loop with our unique TipOne® recycling service. Because all TipOne® system components are made from polypropylene (PP), our service allows high quality recycling of returned TipOne® plastic.

As of January 2025, TipOne® racks made in Germany include post-consumer recyclate collected by our customers using the TipOne® reycling service.

Why is closed-loop recycling a game changer?

- keeps material in the production cycle, reducing the need for new raw material

- thus reducing raw material use, and conserving natural resources

- using recycled PP lowers CO2 emissions compared to the use of virgin PP

Together with our eco-conscious customers using the TipOne® recycling service, we're paving the way to a sustainable future.

This achievement is the result of a decade-long dedication. Below you can dive into the steps taken to make closed-loop recycling possible.

Our journey to closing the loop.

Why choose TipOne®

TipOne® tips are more than just pieces of plastic; they are the foundation of accurate and precise scientific research.

Quality and precision you can trust

Starlab understands that the quality of your pipette tip is crucial for your experiments. Our expertise in design and injection moulding ensures that you get high-quality pipette tips every time, without compromise.

One tip fits all!

TipOne® pipette tips are engineered to fit all popular pipettes, ensuring no loss of accuracy or precision. The universal tip fit, alongside a commitment to reducing plastic waste, is why TipOne® is the go-to choice for scientists who demand reliable performance and sustainable solutions

Please note: Video created prior to July 2023

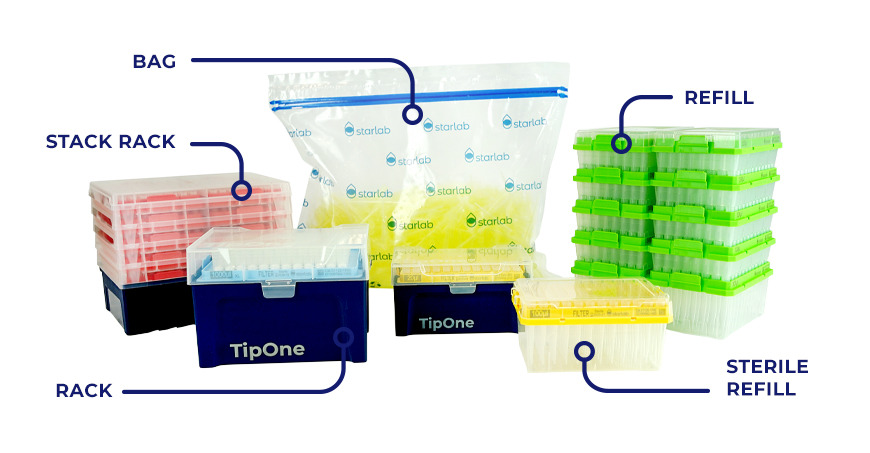

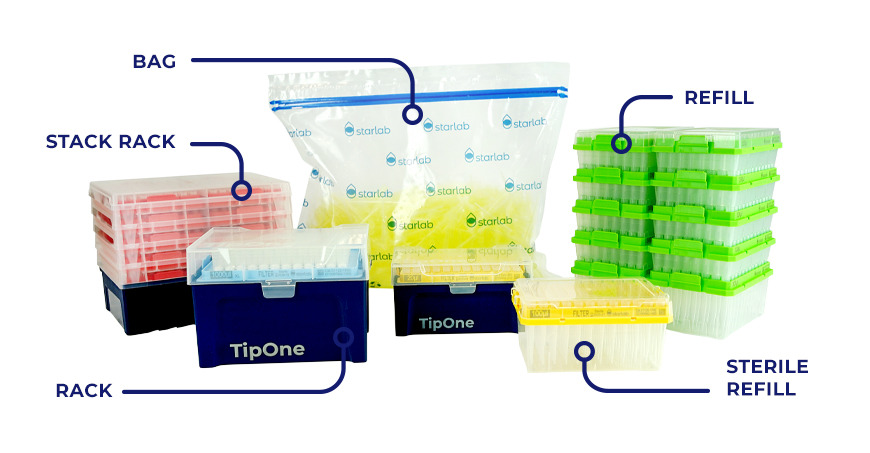

A system, with a system!

TipOne® is a complete system that offers a range of pack types to suit all pipetting needs. TipOne® tips are available in volumes 10 µl to 1250 µl across all pack types, including sterile and filter tip options.

See our overview which provides an easy to follow table showing all TipOne® tips and the pack types available.

TipOne® resources

FAQs

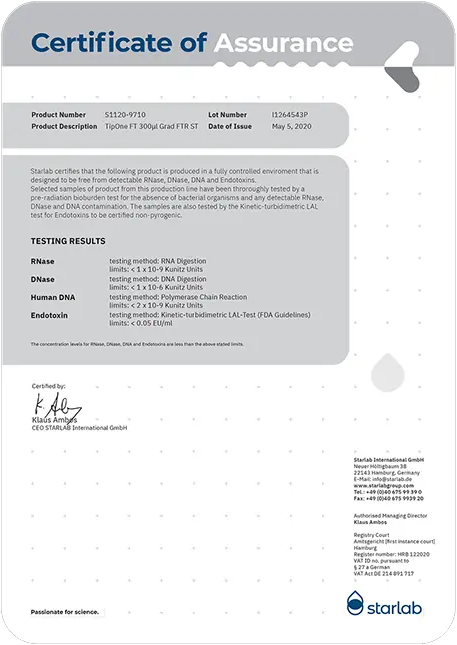

Q: How can I be sure your closed-loop recycling process is genuine and transparent?

A: Certified and audited: Our process is certified by the German government and Starlab is ISO 9001:2015 and ISO 14001:2015 certified, meaning our systems are audited by third parties. Trusted partners: We work with well-known business partners, including REMONDIS, experts in plastics recycling, who handle the polypropylene (PP) grinding. Traceable process: Recycling is collected by couriers and taken to central hubs, ensuring traceability at every step. Visible proof: You may notice small specks or coloured marks in components made with recycled material—clear evidence of recycled PP being used.

Q: Why is closed-loop recycling better than regular recycling?

A: While all recycling helps reduce waste, closed-loop recycling goes further by keeping materials at the same quality and reusing them in the same products. This creates a sustainable cycle (that reduces the need for new raw materials, and lowers the carbon footprint) because high-quality recycled PP is used again and again for the same high-quality products.

Q: What happens if recycling collection targets are not met?

A: Starlab maintains a backup inventory to ensure production continues smoothly. However, successful closed-loop recycling does rely on participation from everyone—Starlab, our customers, and our recycling partner—to keep a steady supply of material.

Q: Is closed-loop recycling better than using bioplastics?

A: Closed-loop recycling and bioplastics are both sustainable options, but they work differently. Bioplastics turn waste (like used frying fat) into new materials, while closed-loop recycling keeps existing materials in use through a circular economy. Both approaches help reduce CO₂ emissions, but in different ways.

Q: Why is recycled plastic from a different source used for the transparent, refill components?

A: The TipOne® plastic we collect and recycle, is a mix of coloured (eg. blue rack base, yellow, red, blue, green tip wafers) and transparent PP (eg. refill packaging, rack lid). This isn’t suitable for making clear parts: transparent components require recyclate made only from transparent PP.

Q: What percentage of TipOne® recyclate is currently used for the TipOne® racks made in Germany?

A: The racks made in Germany are made entirely from recycled plastic. The rack base contains 75% TipOne® recyclate: so the 25% other material in the base, and the lid, is made with the recyclate 'from a different source'.